Your picking and packing process can make or break your order fulfilment. It’s that important. That said, the pick and pack part of fulfilling orders can be super labour and resource intensive. In fact, industry reports estimate that warehouse picking accounts for up to 55% of a distribution centre’s operating costs. If this sounds familiar, you probably want to cut those costs, right?

The good news is, there are loads of ways you can optimise your picking and packing process. Not only will it put a smile on the face of your warehouse staff, it will delight your customers too.

In this article we will discuss:

- What is picking and packing?

- Types of pick and pack processes

- Combining pick and pack strategies

- Which pick and pack strategy do you choose?

- Picking and packing best practices

- Improve your picking and packing process with Sendcloud

- Conclusion

What is picking and packing?

You probably don’t need to be told what picking and packing are. But in case you need a refresher, here’s a quick summary.

Picking is taking the right type and number of items from your warehouse shelves and adding them to customer orders.

Packing is putting products (and additional items such as a pre-printed return label) in boxes, envelopes or other suitable containers before printing the shipping labels and sending them off to your customers.

Combined, picking and packing form part of your order fulfilment process.

Types of pick and pack processes

There are four pick and pack methods commonly used by businesses to fulfil orders. They are:

1. Piece picking

Piece picking – sometimes called discrete picking – is the preferred pick and pack method for smaller businesses. It involves picking and packing orders one at a time. Sounds like a lot of work, right? Not if you have a small product catalogue and order volumes.

Essentially, you take the packing slip of one order, and pick the items off the shelves around your warehouse. Once the order items have been gathered, you take them to a packing station ready for packaging and shipping.

For smaller businesses, piece picking is a clean, convenient and manageable process that reduces mistakes. Some even automate the process, leading to the rise of the robots. According to Digital Journal, the piece picking robot market is expected to be worth $430 million by 2027.

2. Batch picking

Batch picking is the next level up from piece picking. It’s a bit more up tempo, but still manageable. If you’re getting enough orders to arrange them into batches, then batch picking will be the right fit for your warehouse.

Batch picking is best for picking and packing items that are in the same location in your warehouse. It gives your pickers and packers the most efficient route around the warehouse. If you consider that pickers spend a lot of ‘dead time’ (roughly 55%) wandering around the warehouse in between picks, a more efficient route cuts out any backtracking and orders get picked faster.

Warehouse staff will thank you for batch picking because it stops them having to make multiple trips round the warehouse, even if it does get there 10,000 steps in. It means you can get orders shipped faster too, keeping your customers happy.

3. Zone picking

If you have a sizeable warehouse and a good-sized pick and pack crew, zone picking (sometimes called pick and pass) could be ideal for your business. You simply assign your warehouse staff different zones and they stick to picking items in their designated zone.

What if items for a single order are in different zones? Who picks them? That’s when zone picking comes into its own. Let’s say you have a zone A and a zone B. The picker in zone A will gather the items in their zone, then pass it on to the picker in zone B to complete the order. Job done.

That said, zone picking does require some serious organisation and coordination. But if you can pull it off, you can greatly reduce the leg work of your warehouse staff, ease congestion and boost productivity.

💡 Quick tip: Integrating a Warehouse Management System (WMS) can make zone picking even easier.

4. Wave picking

This is not warehouse staff waving to each other as they go about picking items. Wave picking, sometimes called cluster picking, is a combination of piece and batch picking or batch and zonal picking.

The idea is to fulfill groups of similar orders during scheduled times, or waves, using a combo of warehouse picking strategies. Think of wave picking as a hybrid pick and pack strategy.

The orders might have similar stock keeping units (SKUs), similar shipping deadlines, or they could simply be in close proximity to each other.

Wave picking can improve workflows, enhance tracking, improve order and shipping accuracy while reducing errors.

Combining pick and pack strategies

You don’t have to stick to one pick and pack strategy. If it makes sense, you can combine pick and pack processes. For example, you can pair zone picking with batch picking and wave picking. You can even have a blend of zone, batch and wave picking for the ultimate strategy.

That said, this method can make things more complex, but if you can pull it off, it comes with mega benefits, including:

- Fast, efficient pick and pack cycles

- Reduced number of touches per item

- More orders out the door

- Fully unified warehouse operation

Worth looking into if you ask us!

Which pick and pack strategy do you choose?

The pick and pack strategy that’s right for you will depend on where your business is at. If you’re a small business with few orders, piece picking is perfect. You can build up to batch picking, and when business is really booming, you can make the leap to zonal or wave picking, maybe even a hybrid model.

If you’re already shipping a boat load of orders, you’re probably looking at zonal or wave picking. That said, a lot of bigger businesses like a hybrid model.

Whether you’re a small or big business, the pick and pack strategy you choose needs to integrate with any existing systems. For example, the pick and pack stage is the penultimate process to shipping. Does it make sense to integrate your shipping into your pick and pack strategy? You bet it does.

Picking and packing best practices

Now you’ve got an idea of the types of pick and pack strategies available, and which is potentially the right fit for your business, here’s how you make it work practically:

1. Make picking and packing routes flow

The best place to start with your pick and pack process is to get your warehouse organised. This should be done based on how your inventory travels through each area of your facility.

Whether it’s receiving items, storage, replenishment, picking, sorting, packing and preparing for shipment, each function should logically lead to the next one. This stops warehouse staff from having to double back or perform a later function while on the way to an earlier one.

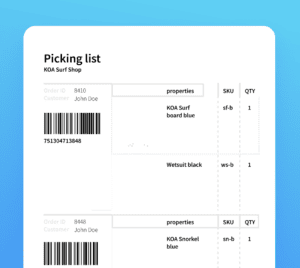

To help you optimise your picking and packing flows, Sendcloud offers the ability to customise the settings of your picking lists to match your chosen picking strategy.

Equally, you can use signage to help your warehouse crew quickly find their way around. This is especially useful for new hires, and if you decide to change things around in your facility at any point.

Plus, your picking and packing strategy can be greatly improved by storing your most popular products near the packing station for easier access.

On the packing side of things, it’s worth having a designated packing zone, and the option to automatically select the right box sizes for packing which you can find as part of a shipping solution like Sendcloud. One of the holdups in the packing process is finding the right containers for packing items ordered. Using the Sendcloud Boxes feature immediately reduces delays and improves warehouse flow.

2. Use barcode scanning to reduce errors

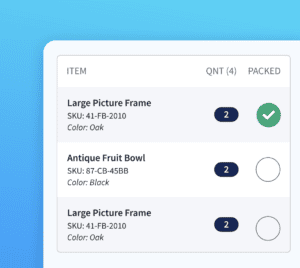

To make picking and packing less labour-intensive, which often leads to mispicks resulting in costly errors and unhappy customers, use mobile barcode scanners to bump up order accuracy rates.

Picking seems to get all the attention when it comes to optimizing the pick and pack process. However, item packing can be optimised too. One of the typical hold-ups when it comes to boxing up orders is labels and packing slips ending up everywhere or going missing. Equally, some order items are missed in the picking process. This causes chaos and delays.

What you need is a way to scan off items before boxing them up. Sendcloud’s Item Packing feature gives you an extra packing check before creating a label. You can scan items before putting them into a box and this ensures that the correct item is scanned and ticked off in your account. If the item is incorrect, a notification will pop up, telling you that you are packing the wrong item.

Plus, you can print pick lists and packing slips, together with your shipping labels, which means that orders can immediately be prepared for shipment. You’re not having to scurry around trying to find labels or having to retrieve missed items. The moment that an order hits the packing station it’s ready to go.

3. Integrate a warehouse management system (WMS)

Warehouse Management Systems have fast become the cornerstone of order fulfilment, helping to streamline picking and packing systems in the process. In 2018, WMS adoption exceeded 90% for the first time. This alone demonstrates the value of a good WMS and how it’s transforming picking and packing processes for the better.

If your business is growing and looking to scale, a WMS will help you on the journey. Plus, you can automate many of your repetitive workflows to further boost the efficiency of your picking and packing process, and much more. Are you looking to integrate a WMS? Then make sure to check out our blog with the 20 most popular WMS systems.

4. Train warehouse staff

Amid getting your warehouse organised, deploying barcode scanners, integrating a WMS and other stuff to optimise your pick and pack process, don’t forget about training your staff. After all, these are the people that will need to rely on these systems and processes to do their job.

An optimised pick and pack process is only as strong as your staff. To ensure that everyone is working to the same standards, and pulling together to achieve your objectives, set time aside to train staff.

This includes training on warehouse layout, using scanners and all the other things that come with making your pick and pack process as smooth as possible. As an added bonus, investing in training can actually improve staff morale.

If your business doesn’t work with a WMS yet, Sendcloud’s Pack & Go feature is the perfect solution to make your picking and packing process as easy as possible for your warehouse staff. With our automatic mode, your staff can process orders and print labels in just one click. Or they can pick up a handheld scanner to process and print labels directly from picking slips or packing lists via scanner mode.

Improve your picking and packing process with Sendcloud

Achieving an optimised pick and pack process requires help. Whether you ship 300 or 3,000 parcels per month, prepping those orders, error-free, requires something that slots right into your existing systems.

With Sendcloud your staff can pick, pack and ship smarter, without disrupting your workflows. In fact, you can adjust your pick and pack process to fit the needs of your warehouse staff. Besides, Pack & Go is a great alternative to a more expensive and slow to implement Warehouse Management System.

See for yourself what Sendcloud can do for your business with a demo with one of our shipping specialists.

Conclusion

Your pick and pack process is the pathway to better shipping and more satisfied customers. Optimised in the right way, you can deliver an outstanding customer experience every time. That said, picking and packing is just one part of a much bigger process.

To really power-up your pick and pack process, it’s worth integrating a shipping platform to build custom workflows for picking, packing and shipping. This not only saves you time and money on every single package, it improves your customer experience.